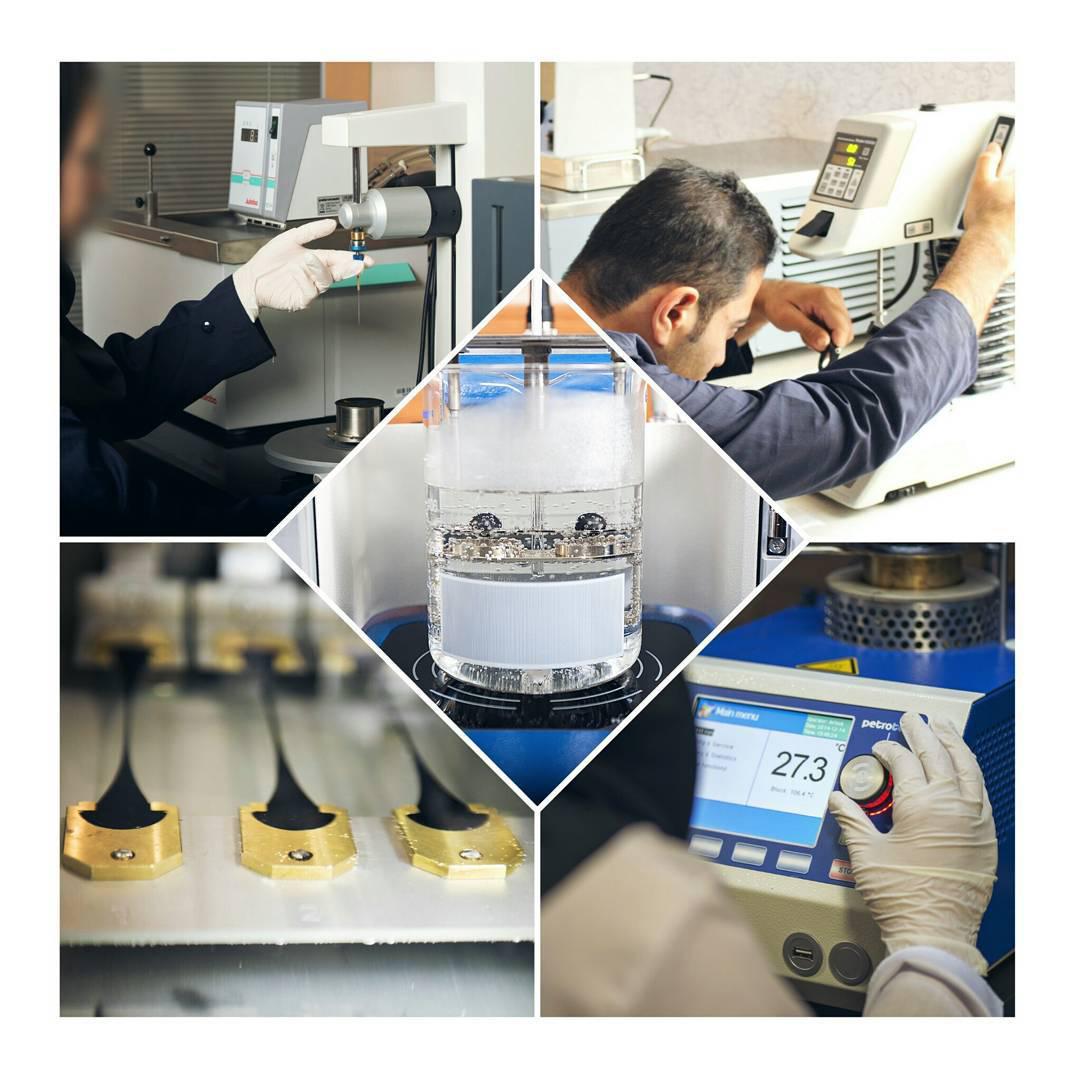

Testing Asphalt Emulsion

Testing Asphalt Emulsion

What are the primary reasons for testing and examining an asphalt emulsion?

There are three specific purposes for testing asphalt emulsion. They are as follows:

- To provide data for specification requirements

- To control the quality and uniformity of the product during manufacturing and use.

- To predict and control the handling, storage, and field performance properties of the material.

Where can the specifications and test procedures for testing asphalt emulsion be found?

Two primary sources exist for finding specifications and test procedures for asphalt emulsions. The American Society For Testing and Materials (ASTM) and The American Association of State Highway and Transportation Officials (AASHTO) are generally the most widely accepted sources for determining specifications and test procedures. However, within many state highway organizations, additional specification and test procedures may exist.

In what way can one asphalt emulsion be distinguished from another?

The particle charge test is used to identify the charge associated with a particular asphalt emulsion. Immersing a positive electrode and a negative electrode into an emulsion sample performs the test. The electrodes are then connected to a controlled direct-current electrical source. At the end of the test period, the electrodes are observed. If there is an appreciable layer of asphalt determined on the negative electrode then the emulsion is cationic.

Is there a test to determine the viscosity of a particular emulsion?

Viscosity is defined as a fluid’s resistance to flow. For asphalt emulsions, the Saybol Furol viscosity test is used as a measure of viscosity. Depending on the type of emulsion, one of two testing temperatures are used, 25 C and 50 C (77 F and 122 F).

Are there any tests used to determine the ability of an asphalt emulsion to coat an aggregate?

Yes, the field coating test and water resistance test are used to determine the ability of the asphalt emulsion to coat the job aggregate, the ability of the emulsion to withstand mixing, and the ability to resist the washing action of water after the completion of mixing. This test is primarily used to identify medium-setting asphalt emulsions suitable for mixing with coarse-graded aggregates.

How can it be determined exactly how much asphalt is present in a sample of asphalt emulsion?

A distillation is performed under controlled conditions to extract the light oil and water from a sample of asphalt emulsion. What is leftover is the asphalt residue from the asphalt emulsion. This residue is expressed as a percentage by weight of the total sample. Additional tests may be run on the residue to determine the physical properties of the end-use asphalt.

What types of tests exist to determine the properties of the asphalt residue after it has been distilled?

There are many different types of tests that can be performed on asphalt emulsion residue. They measure the ductility, solubility, hardness, elasticity, and resistance to flow at elevated temperatures. AASHTO and ASTM have developed several tests to determine these properties