Bitumen Primer D 41

Manufacturer of Iran Bitumen Primer D 41

RAHA Bitumen Primer D 41 is an asphaltic primer suitable for uses in roofing. dampproofing and waterproofing. It is manufactured as a surface dressing to masonry or concrete to Improve the bond of bituminous materials.

Primer D 41 is an excellent quality universal primer, manufactured from a special type of bitumen. It is solvent based and commonly applied onto various substrates (concrete, concrete blocks, bricks, foam concrete, fiber and steel substrates) to improve bonding of bituminous products. RAHA Bitumen Primer D 41 is in accordance with ASTM D 41.

Iran bitumen primer D 41 is like as cutback asphalt using undercoating in siding and roofing applications including shingling or acoustical installations. Without further fractionation or at least partial replacement of the asphalt volatile solvent materials, prior primer compositions do not provide desired adhesion between an overlaid sheet and the substrate. By the addition of the present halobenzotrifluoride solvent, the volatile content is reduced to 200 g/l maximum or less and the flash point of the liquid cutback asphalt is raised by at least 5°. Further, the tacky modified primer composition described herein provides additional benefits, such as compatibility with a wide variety of substrate surfaces including metal, felt, fiber board, plaster board, and wood substrates. When coated over a plywood roof deck, the present composition lubricates and preserves the wood substrate.

Bitumen primer content

To liquid cutback asphalt, containing 30 wt.% of mineral spirits solvent was added 10 wt.% of p-bromobenzotrifluoride to provide a liquid bitumen primer D 41 having a VOC concentration of 186 gll and a flash point of 110°F. The resulting bitumen primer D 41 composition was rolled at ambient temperature on a plywood roof deck in a 6 mil thick layer. Alternatively, the composition can be sprayed or poured on the deck. The primer layer was then covered with an asphaltic base sheet which was nailed to the deck through the primer under ambient temperature conditions. A granular surfaced bitumen cap sheet was then applied over the secured base sheet by torching.

Bitumen primer adhesive

The above experiment was repeated except that a non-modified a bitumen primer D 41, namely liquid cutback asphalt of 70 wt.% asphalt and 30 wt.% mineral spirits solvent was substituted for the halobenzotrifluoride solvent described above. The result of bitumen primer D 41 had a VOC concentration of about 450 g/I and showed inferior adhesion to the roof deck.

It will be understood that many modifications and alterations can be made in the above bitumen primer D 41 composition by addition of conventional excipients such as a thickener or diluent to alter its viscosity, or adhesive such as a pressure-sensitive adhesive, without departing from the scope of this invention.

Modified bitumen primer

The present modified primer, which is a tacky, oily substance, is coated on the substrate as a layer in a thickness of from about 0.75 to about 12 mils, preferably a thickness of from 1-7 mils on a roof deck and then covered with one or more top layers of asphaltic material to provide a weather resistant exposed surface, e.g. A granule coated membrane on the weather-exposed surface of the installation according to with current specifications. More particularly, according to current specifications, installation generally involves applying a pacifying amount of the present primer composition to a substrate such as a new roof deck or an existing roof, or a siding or acoustical base surface. By way of illustration on a new roof, after applying the primer composition, an asphaltic base sheet is nailed to the deck through the layer of primer and a weather resistant, bitumen modified cap sheet is torched over the base sheet to complete the installation. The resulting installation possesses markedly reduced VOC concentration, rapid drying within 1-5 minutes and a flash temperature above 100°F.

Having generally described the invention, reference is had to the following examples which illustrate preferred embodiments and comparisons but which are not to be construed as limiting to the scope of the invention as set forth above and in the appended claims.

Features of Bitumen Primer D 41

- Improves the bond of bituminous materials

- Binder for dust particles

- Surface dressing to masonry and metal surfaces

- Conforms to the requirements of ASTM D 41, Type I

- Conforms to SASO 2057

- Water-resistant.

- Corrosion and chemical resistant.

- Penetrates and seals porous surfaces.

- Fast drying.

- Cost-effective, no heating, thinning or mixing.

- Compatible with various substrates and structures.

Uses of Bitumen Primer D 41

Suitable for use with asphalt in roofing, dampproofing, and waterproofing below or above ground level, for application to concrete. masonry, metal and asphalt surfaces. Also used as a primer coat to receive membranes or liquid as asphalts and asphalt products.

Main Uses:

The universal primer on roofs and walls made from reinforced concrete, asphalt, bricks, metal and porous substrates before applying any of Duproof waterproofing sheet membranes and protective coatings.

Single coat protective coating on various construction structures and on metal structures. It can be applied on vertical and horizontal structures.

Instructions for Application

Primer D 41 should be thoroughly stirred before use. The surface should be dry, clean and free of loose materials, dirt, soil, grease, oil or other impurities.

Apply Bitumen Primer D 41 by means of a brush, roller or spray gun @ of 5-6 m²/lit into the entire coverage area of the substrate and allow to dry. The drying time and coverage depends on the porosity of the substrate and the environmental conditions.

Cleaning

the Primer can be removed from equipment and tools with any suitable solvent such as gasoline or kerosene.

Coverage

Approximate rate : 0.2 – 0.3 kg/m2. The exact rate will depend upon the porosity or smoothness of the surface.

HEALTH & SAFETY

Personnel should wear protective masks, gloves, and goggles during application.

Precautions

RAHA Bitumen Primer D 41 contains volatile solvent and has a low flash point. Care must be taken to ensure that there is adequate ventilation in the working lace. Fires and naked flames should be kept at a distance.

Storage

Store in a dry and shaded area in original packing. The container should be kept covered while working in order to prevent the evaporation of the solvent.

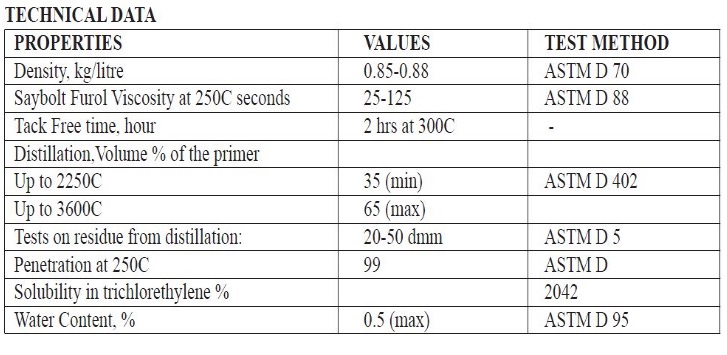

Specification of Bitumen Primer D 41

DATA SHEET OF BITUMEN PRIMER D-41