Chip Seal

Bitumen Emulsion for Chip Seal

The asphalt surface of the roads can experience erosion, raveling, loss of aggregate,honeycombing, and sulphate attacks over time due to weather conditions such as frost, sunlight, heat, and also road salting, snow removal, as well as the effects of excessive loading and friction, especially caused by tire chains and snowplow blades. Failing to repair and install overlay asphalt in due time will allow damages to expand, leading to complete destruction of the road surface and even the underlying layers. The use of protective layers is recommended to prevent intensification of asphalt wear out, postpone overlay installation, maintain the existing conditions, and fill the cracks.

In addition to providing a suitable road surface, these layers will waterproof it and prevent the destruction of asphalt and its underlying layers. This is a cheap maintenance method that will ensure uninterrupted and secure operation of the roads. Different methods are recommended based on the degree of destruction, the weight and volume of traffic, and type of asphalt. These methods are inexpensive and can be employed early after or even before the beginning of asphalt pavement distress.

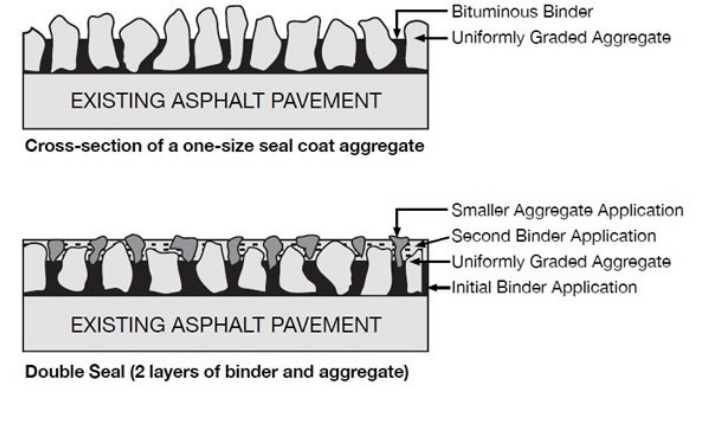

A Chip Seal is the application of asphalt emulsion to an existing surface followed by a layer of aggregate chips. The surface is then rolled to embed the aggregate chips into the asphalt emulsion. Our Chip Seal emulsions are designed and formulated to perform under various project conditions. The addition of polymer and rejuvenating agents to our standard Chip Seal Oil increase workability and aggregate chip retention.

Applying a layer of CRS bitumen emulsion and a layer of aggregates on it. That is suitable for the surfaces on which about 300 vehicles pass daily. In case the road is busy or there is a high traffic street, we must implement an asphalt layer or one or two Slurry Seal layers or one or two Micro-surfacing layers after applying Chip Seal.

How is a chip seal applied?

First, repair potholes and seal large cracks in the old road surface. Allow enough curing time for these treatments before applying the chip seal. Prior to chip seal application clean the road surface using a power sweeper or rotary broom. An asphalt emulsion is then uniformly spray-applied by an asphalt emulsion distributor and then chips are applied evenly by using a self-propelled or a truck-attached mechanical spreader. A Pneumatic-tired roller is then used to embed the aggregate into the asphalt film. Finally, loose particles are removed after the chip seal treatment has cured completely.

What types of asphalt emulsions are used for chip seal?

Typical asphalt emulsions used in chip seals are CRS-2, RS-2, or HFRS-2. Additionally, for higher volume traffic roadways polymer modified versions of these asphalt emulsions can be used.

Is there any advantage in using an asphalt emulsion over hot asphalt in the chip seal application process?

Asphalt emulsions are applied at much lower temperatures. Thus, there is energy savings and improved safety when applying a chip seal using asphalt emulsions.

What are some keys to a successful chip seal surface treatment?

- Coordinate construction to ensure continuous operation.

- Use hard, cubical, and clean aggregate.

- Properly calibrate application equipment.

- Maintain traffic control while chip seal application cures.

Chip Seal applications and facts:

- After applying Chip Seal, we can implement Slurry Seal or Micro-surfacing to fill the voids between aggregates and to have a black and monotonous surface.

- It prevents bitumen emulsion from freezing which is under and over its layer.

- It improves surface texture, waterproofs the surface and protects the underlying pavement from oxidation, fatigue, aging as well as traffic wear.

- It gives new life to dry and weathered surfaces and seals small cracks and imperfections.

- It is an economical way to resurface roads.

- Size of aggregates must be 6 to 12 mm.