Polymer Modified Bitumen

Bitumen has been used for thousands of years and its importance as a valued engineering material continues to increase. The interest in the modification of bitumen using polymers, whether virgin, scrap or polymer blends, is intense. The last two decades, in particular, have seen an increase in the number of academic groups studying polymer-modified bitumen and correspondingly the peer-reviewed literature in the field has increased. Initially, studies on polymer modified bitumen focused more on engineering and empirical measurements, e.g. ageing and softening point. However, in recent years a plethora of techniques have been employed in the study of the effect of the addition of polymers on a range of bitumen properties, polymer—bitumen morphology and polymer—bitumen interactions.

Polymer modified bitumen (PMB) is one of the specially designed and engineered bitumen grades that are used in making pavement, roads for heavy duty traffic and home roofing solutions to withstand extreme weather conditions. PMB is a normal bitumen with the added polymer, which gives it extra strength, high cohesiveness and resistance to fatigue, stripping and deformations, making it a favorable material for infrastructure.

Pavements designed and constructed for heavy-duty traffic and extreme weather conditions require specially designed engineered Bitumen Grades. By changing the characteristics of normal bitumen with the addition of a polymer, either they are of elastomeric nature or elastomeric, we succeed to obtain bitumen that allows the mixture to be more cohesive, with much more strength and significant higher resistance to parameters like fatigue and permanent deformations for road pavements.

When a polymer is added to regular bitumen, it becomes more elastomeric, which provides it with additional elasticity. The polymer that is added is styrene butadiene styrene (SBS), which acts as a binder modification agent. The primary objective of SBS polymer modified bitumen is to provide extra life to pavement, roads and construction designs. Some of the qualities exhibited by PMB are:

- Higher rigidity

- Increased resistance to deformation

- Increased resistance to cracks and stripping

- Better water resistance properties

- High durability

Advantage of using polymer modified bitumen

- stronger road with increased marshall stability value and greater Rigidity.

- better resistant towards rainwater and water stagnation.

- no stripping and no potholes.

- Better resistance to permanent deformation

- reduction in pores in aggregate and hence less rutting and raveling.

- Much higher durability

Common types of polymer modified bitumen

The following table lists some common asphalt cement and HMA modifiers and their general purpose/use.

| type | General Purpose or Use | Generic Examples |

| filler | Fill voids and therefore reduce optimum asphalt content Meet aggregate gradation specifications Increase stability Improve the asphalt cement-aggregate bond |

Mineral filler crusher fines lime Portland cement fly ash Carbon black |

| extender | Substituted for a portion of asphalt cement (typically between 20–35 % by weight of total asphalt binder) to decrease the amount of asphalt cement required | Sulfur Lignin |

| rubber | Increase HMA stiffness at high service temperatures Increase HMA elasticity at medium service temperatures to resist fatigue cracking Decrease HMA stiffness at low temperatures to resist thermal cracking (see Figure 2) |

Natural Latex Synthetic latex (e.g., Polychloroprene latex) Block copolymer (e.g., Styrene-butadiene-styrene (SBS)) Reclaimed rubber (e.g., crumb rubber from old tires) |

| plastic | Polyethylene/polypropylene Ethylene acrylate copolymer Ethyl-vinyl-acetate (EVA) Polyvinyl chloride (PVC) Ethylene propylene or EPDM Polyolefin |

|

| Rubber-Plastic Combinations | Blends of rubber and plastic | |

| Fiber | Improving tensile strength of HMA Mixtures Improving cohesion of HMA Mixtures Permit higher asphalt content without the significant increase in the drain down |

Natural: Asbestos Rock wool Manufactured: Polypropylene Polyester Fiberglass Mineral Cellulose |

| Oxidant | Increase HMA stiffness after the HMA is placed | Manganese salts |

| Antioxidant | Increase the durability of HMA mixtures by retarding their oxidation | Lead compounds Carbon Calcium salts |

| Hydrocarbon | Restore aged asphalt cement to current specifications Increase HMA stiffness in general |

Recycling and rejuvenating oils Hard and natural asphalts |

| Antistripping Agents | Minimize stripping of asphalt cement from aggregates | Amines Lime |

| Waste Materials | Replace aggregate or asphalt volume with a cheaper waste product | Roofing shingles Recycled Tires Glass |

Use as needed

While the benefits of using modified asphalts are widely acknowledged, not all asphalt mixes or treatments need to be modified. Each application should be evaluated to determine if the traffic loading, anticipated service life, environmental conditions and desired performance justify the use of modifiers. Modified asphalts can be a good investment.

- The rheological properties of conventional binders may be modified by the introduction of:

- Elastomers;

- Plastomers;

- Crumb rubber;

- The modification is costly and is normally justified when bituminous surfacing are subjected to severe conditions such as:

- Steep gradients;

- Very high road surface temperature;

- High traffic loading; or

- Heavily trafficked intersections.

- Modification may also be advantageous for surfacing on highly flexible and cracked pavements, where an improvement in the rheological properties of the bitumen is required.

- Use in such applications should be guided by expert opinion.

- In addition to the primary aims above, the range of properties improved include

- Durability;

- Aggregate retention;

- Resistance to permanent deformation;

- Resistance to fatigue cracking;

- Cohesion (internal strength);

- Elasticity;

- Viscosity less susceptible to temperature changes.

- Modification agents

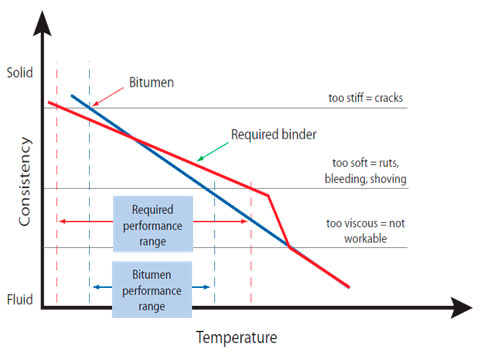

- The primary aim of the modification of bitumen for use in structural layers is to increase the resistance of these layers to permanent deformation at high road temperatures without compromising the properties of these layers over the rest of the prevailing temperature range.

- The use of polymer modified bitumen to obtain improved performance is rising as a result of increases in tire pressures, axle loads, and higher traffic volumes.

- Improved performance can be achieved in two ways, both of which are aimed at reducing the permanent strain:

- An increase in the elastic component with an associated reduction in the viscous component; and

- Stiffening of the bitumen to reduce the total viscoelastic response of the layer.

The modification is achieved by the introduction of polymers (including crumb rubber), aliphatic synthetic wax or naturally occurring hydrocarbons.

Polymers can be broadly categorized as “elastomers” (sometimes referred to as thermoplastic elastomers) for improving the strength and elastic properties of a binder, and “plastomers” (sometimes referred to as

thermoplastic polymers) for increasing the viscosity of the bitumen.