Performance Grade (PG) Bitumen

General Description of Performance Grade (PG) Bitumen

Due to the inadequacy of penetration and viscosity based grading systems, the Strategic Highway Research Program (SHRP) in the US conducted a Project between 1987 and 1993 in order to overcome the shortcomings of empirical systems. One consequence of this Project was a performance-based binder specification with a new set of tests. The final product of the SHRP bitumen research program is a new system referred to as SUPERPAVE, which stands for Superior Performing Asphalt Pavements and called as binder specification because it is intended to function equally well for modified and unmodified bitumens. Performance Grade (PG) Bitumen is bitumen which is graded based on its performance at different temperatures. In Superpave grading system, binders are classified according to their performance in extreme hot and cold temperatures and called as performance grade (PG) bitumen. The main purpose of grading and selecting asphalt binder using the PG system is to make certain that the binder has the appropriate properties for environmental conditions in the field. PG asphalt binders are selected to meet expected climatic conditions as well as traffic speed and volume adjustments. Therefore, the PG system uses a common set of tests to measure physical properties of the binder that can be directly related to field performance of the pavement at its service temperatures by engineering principles. It is one of the most important changes introduced in Super pave that acceptance limits are the same but have to be met at specific pavement temperature and traffic conditions.

The Long-Term Pavement Performance (LTPP) has given a certain algorithm to calculate the temperature of the pavement based on the temperature of the air above. From this, the highest and the lowest temperatures of the pavement are calculated and the bitumen that performs well in that temperature range is selected. Penetration grading and viscosity grading are somewhat limited in their ability to fully characterize asphalt binder for use in Hot Mix Asphalt (HMA) pavement. Therefore, as part of the Superpave research effort, new binder tests and specifications were developed to more accurately and fully characterize asphalt binders for use in HMA pavements. These tests and specifications are specifically designed to address HMA pavement performance parameters such as rutting, fatigue cracking, and thermal cracking. Superpave performance Grade (PG) Bitumen is based on the idea that an HMA asphalt binder’s properties should be related to the conditions under which it is used. For asphalt binders, this involves expected climatic conditions as well as aging considerations. Therefore, the PG system uses a common battery of tests (as the older penetration and viscosity grading systems do) but specifies that a particular asphalt binder must pass these tests at specific temperatures that are dependent upon the specific climatic conditions in the area of use. This concept is not new – selection of penetration or viscosity graded asphalt binders follows the same logic – but the relationships between asphalt binder properties and conditions of use are more complete and more precise with the Superpave PG system. Information on how to select a PG asphalt binder for a specific condition is contained in Superpave mix design method. Table below shows how the Superpave PG system addresses specific penetration, AC, and AR grading system general limitations.

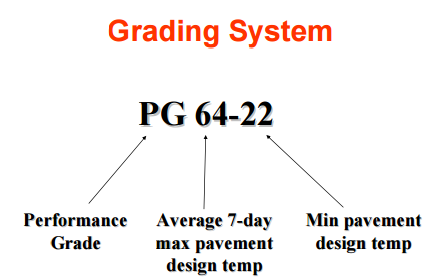

Performance Grade (PG) Bitumen Nomenclature

Performance Grade (PG) bitumen cement based on two factors: traffic and pavement temperature. Adjustments are made to the PG grade of asphalt cement based on traffic conditions and traffic volumes which are intended to enhance the design life of the pavement. The PG grading system is defined by two numbers, which represent pavement temperatures. The first number PG 64-XX represents the high pavement temperature in degrees Celsius, while the second number PG XX-22 represents the low pavement temperature. Notice that these numbers are pavement temperatures and not air temperatures (these pavement temperatures are estimated from air temperatures using an algorithm contained in the LTPP Bind program). All adjustments to the PG grading system are made in six (6) degree increments. The high temperature relates to the effects of rutting and the low temperature relates to cold temperature and fatigue cracking.

Prediction of Performance Grade (PG) Bitumen for different crude oil blends.

Performance Grading Should:

• Include measures describing stress

– strain Relationships under field loading.

• Consider the pavement conditions

– Temperature, traffic speed, traffic volume, and pavement structure.

• Include acceptance limits derived from experience and actual field performance.

Variables that affect Binder Selection

• Geographic Area:

– Air Temperature, solar radiation

– Pavement Temperature: Max & Min

• Traffic volume: High, Medium, Low

• Traffic speed: Fast, Slow

• Pavement Structure: Strong, Weak

– Stress and strain

Methods of Selection

• Select base grade based upon:

–Geographic Area

–Air Temperature

–Pavement Temperature

• Adjust base grade based upon:

–Traffic Speed

–Traffic Volume

Superiorities of Performance Grade (PG) Bitumen

1. Traditional penetration and viscosity bitumen grading systems were developed in accordance with the past experiences. The aim of these empirical procedures is to avoid bad applications in the past and repeat those are successful. Empirical methods can be applicable as long as the past conditions still exist. But, current traffic and climatic conditions are highly different from those prevailed when penetration and viscosity systems were developed, hence past experiences are no longer sufficient to establish binder grading. In PG system, it is possible to use actual traffic volume and vehicle speed which represents the duration of load application.

2. Conventional tests are conducted at unique test temperature which is 25 C in penetration and d 60 C in viscosity test, which means that penetration test does not give any information about low temperature and high-temperature performance. Superpave grading indicates working temperature range of binder. 5th Eurasphalt & Eurobitume Congress, 13-15th June 2012, Istanbul

3. Bitumen is a visco-elastic material where temperature and rate of load application have a great influence on its behavior. Although the behavior of bitumen in lower loading rates corresponds to that of higher temperature, a conventional grading system neither does nor takes into account the rate of load but Superpave does.

4. Binders of different petroleum source may have different rheological behavior even though they are the same penetration or viscosity grade.

5. Conventional methods are used only for unmodified bitumens, whereas Superpave is developed for both modified and unmodified bitumens.

6. Conventional methods do not take into account long-term aging behavior of binders. But Superpave cover both short-term aging using the rolling thin film oven test (RTFOT) and long-term aging using with the pressure aging vessel (PAV).

7. It recognizes that there are three main distress mechanisms affecting pavement performance, rutting, fatigue cracking and thermal cracking. Bitumen plays a very important role in resisting each of these distress mechanisms. 8. Bitumen properties measured at different temperatures contribute to resistance to the distresses in a different level. Bitumen contributing to rutting resistance is measured at maximum pavement temperatures and it favours a more elastic and stiffer binder. Bitumen contributing to fatigue resistance is most critical at average pavement temperatures and while it still favours an elastic binder it requires a softer bitumen. Bitumen contribution to thermal cracking is critical only at minimum pavement temperatures and it favours a less elastic and soft bitumen.

In summary

Superior to viscosity and penetration grading systems

• Have resulted in higher quality binders

• Allow appropriate grade of binder for Allow for a specific location based upon:

– Air and pavement temperature

– loading conditions

– Traffic speed

Compare the performance grade with the penetration and viscosity grade

| Limitations of Penetration, AC and AR Grading Systems | Superpave Binder Testing and Specification Features that Address Prior Limitations |

| Penetration and ductility tests are empirical and not directly related to HMA pavement performance. | The physical properties measured are directly related to field performance by engineering principles. |

| The range of pavement temperatures at any one site is not adequately covered. For example, there is no test method | Test criteria remain constant, however, the temperature at which the criteria must be met changes in consideration of the binder grade selected for the prevalent climatic conditions. |

| Test methods only consider short-term asphalt binder aging (thin film oven test) although long-term aging is a significant factor in fatigue cracking and low temperature cracking. | The entire range of pavement temperatures experienced at a particular site is covered. |

| Asphalt binders can have significantly different characteristics within the same grading category. | Three critical binder ages are simulated and tested: 1. Original asphalt binder prior to mixing with aggregate. 2. Aged asphalt binder after HMA production and construction. 3. Long-term aged binder. |

| Asphalt binders can have significantly different characteristics within the same grading category. | Grading is more precise and there is less overlap between grades. |

| Modified asphalt binders are not suited for these grading systems | Tests and specifications are intended for asphalt “binders” to include both modified and unmodified asphalt cement |

Application of Performance Grade (PG) Bitumen

PG52-28 is primarily used in paving for both new construction and pavement rehabilitation and in both dense-graded and open graded Hot Mix Asphalt (HMA). This product could also be used for sealing of edges of new to told paving and crack sealing. Other uses include spray applications for bridge deck and pavement protective membrane with fabrics.

PG58-22 is primarily used in paving for both new construction and pavement rehabilitation and in both dense-graded and open graded Hot Mix Asphalt (HMA). This product could also be used for sealing of edges of new to told paving and crack sealing. Other uses include spray applications for bridge deck and pavement protective membrane with fabrics.

PG58-28 is primarily used in paving for both new construction and pavement rehabilitation and in both dense-graded and open-graded HMA. Other uses include spray applications for bridge deck and pavement protective membrane with fabrics. PG58-28 is generally used in very cold areas.

PG58-34 is generally used in the upper half of eastern Washington and on higher elevation roadways. PG58-34 is a paving asphalt cement primarily used for the production of Hot Mix Asphalt (HMA). This product could also be used for sealing the edges of new to old paving and crack sealing. PG58-34 is used in paving for both new construction and pavement rehabilitation in both dense-graded and open-graded HMA.

PG58-40 is primarily used on the high elevation roadways. PG58-40 is paving asphalt cement for the production of Hot Mix Asphalt (HMA). This product could also be used for sealing of edges of new to old paving and crack sealing.

PG64-22 is primarily used in paving for both new construction and pavement rehabilitation and in both dense-graded and open graded Hot Mix Asphalt (HMA). This product could also be used for sealing of edges of new to old paving and crack sealing. Other uses include spray applications for bridge deck and pavement protective membrane with fabrics. It has been reported that with proper aggregate characteristics and asphalt content, HMA with PG64-22 as the binder may exhibit less tenderness than a similar mixture with a lower viscosity/softer asphalt. The typical tenderness problems of mixture shoving and checking during rolling and pavement surface scuffing and marking by traffic immediately after paving may be noticeably reduced.

PG64-28 is primarily used in paving for both new construction and pavement rehabilitation and in both dense-graded and open-graded HMA. Other uses include spray applications for bridge deck and pavement protective membrane with fabrics. PG64-28 is generally used for the Lower half of Eastern Washington.

PG70-22 is primarily used in high traffic areas and is also the paving asphalt cement primarily used for the production of Hot Mix Asphalt (HMA). This product could also be used for sealing the edges of pavement and for crack sealing.

Which should PG asphalt perform best in resisting thermal cracking?

• PG 64 -22

• PG 76 -22

• PG 64 -28

• PG 58 -34

Which of the following PG binders should perform best in resisting rutting?

• PG 82 -22

• PG 76 -28

• PG 70 -28

• PG 76 -22

Effect of Traffic Speed and Volume on Binder Selection

• Examples

• Base Grade PG 58 -22

–For toll road – (high Volume) PG 64-22

–For toll booth – (high volume and slow traffic) PG 70-22

–For rest area – (high volume and standing traffic) PG 76-22

Specification of Performance Grade (PG) Bitumen

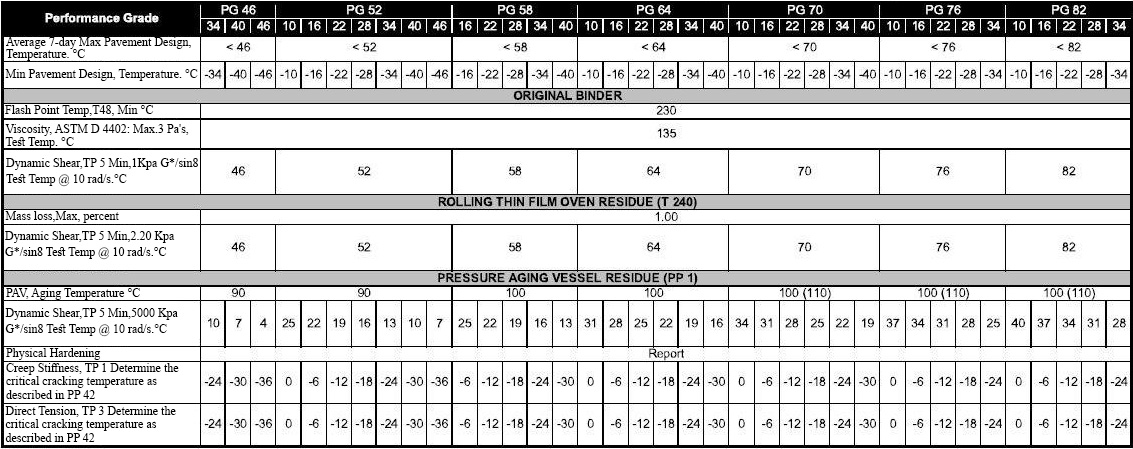

• The table in Figure 2 is the standard summary table presented in the AASHTO MP 1 specification for performance graded asphalt binder. The following items may help to decipher this table:

• The top several rows (all the rows above the “original binder” row) are used to designate the desired PG grade. For instance, if the average 7-day maximum pavement design temperature is greater than 52˚C but less than 58˚C then you should use the “< 58” column. The temperatures directly under the “< 58” cell are selected based on the minimum pavement design temperature in ˚C.

• No matter what the desired PG binder specification, the same tests are run. The PG specification (e.g., PG 58-22) just determines the temperature at which the tests are run.

• Tests are run on the original binder (no simulated aging), RTFO residue (simulated short-term aging) and PAV residue (simulated long-term aging) in order to fully characterize the asphalt binder throughout its life. Notice that often the same test is run on different simulated binder ages. For instance, the dynamic shear test is run on all three simulated binder ages.

• The tests run on the binder are listed in the left-hand column. They are not necessarily listed by their common names but the applicable AASHTO test procedure is listed. For instance, “Flash Point Temp. T 48, Minimum (˚C)” means that the flash point is measured according to AASHTO T 48 and that the value in the adjacent column represents the minimum allowable in degrees Centigrade.

Performance Graded Asphalt Binder Specification

Related Tests

Superpave performance grading uses the following asphalt binder tests:

• Rolling thin film oven (RTFO)

• Pressure aging vessel (PAV)

• Rotational viscometer (RV)

• Dynamic shear rheometer (DSR)

• Bending beam rheometer (BBR)

• Direct tension tester (DTT)