bitumen penetration test

bitumen penetration test and specification

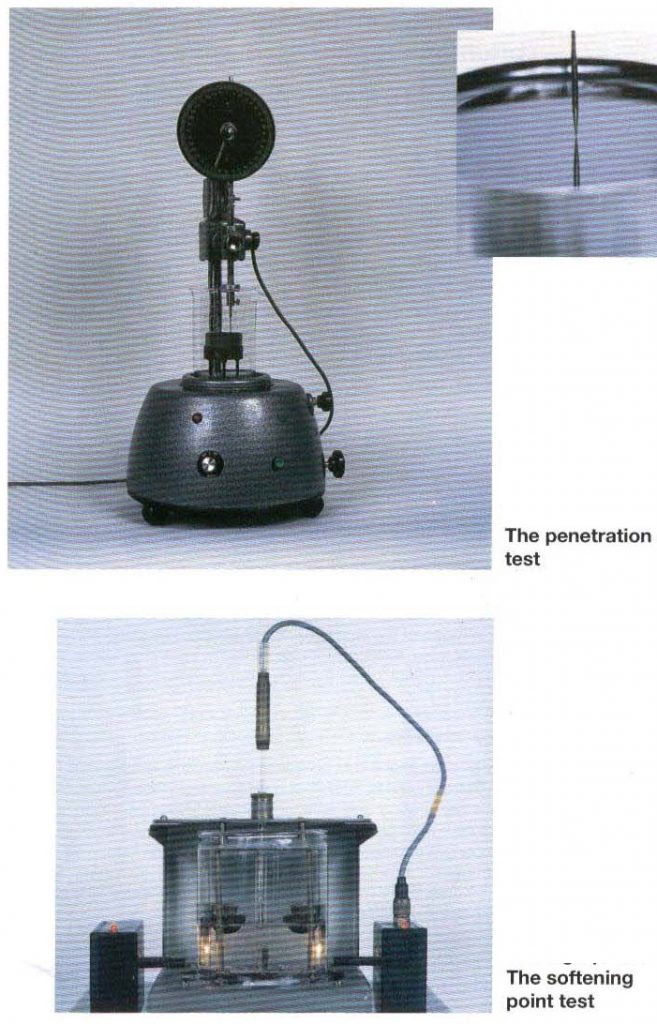

The penetration of a sharp object into a material is the usual criterion of consistency. This is the principle of the well-known penetration test for bitumen which was originally published in 1889. In the form standardised by the ASTM it subsequently became the most frequently used test method. In this test a needle of specified dimensions is allowed to penetrate into a sample of bitumen, under a known load (100 g). at a fixed temperature (25°C), for a known time (5 seconds) .The distance the needle penetrates, in units of decimillimetre, dmm (0.1 mm), is termed the penetration. Therefore the greater the penetration of the needle the softer the bitumen. Penetrations less than 2 and greater than 500 cannot be determined with accuracy and even within this range the specified procedure has to be followed closely to obtain reliable results. This test is the basis upon which penetration grade bitumens are classified into standard penetration ranges. For each test three individual measurements of penetration are made. The average of the three values is recorded to the nearest whole unit. The recorded penetration is reported if the difference between the individual three measurements does not exceed a specified limit.

The acceptable repeatability and reproducibility quoted in IP 49 for the penetration test are as follows:

Repeatability

If the penetration is less than 50 -1 dmm

If the penetration is greater than 50 – 3% of the mean of the two results

Reproducibility

If the penetration is less than 50 -4 dmm

If the penetration is greater than 50 -8% of the mean of the two results.